Hawk Technology is now looking for qualified individuals to fill the following positions. Interested parties may submit resumes to hr@hawktechnology.com for consideration.

Machinist

Sets up and operates conventional, and machining centers to fabricate metallic parts by performing the following duties.

Essential Duties and Responsibilities include the following. Other duties may be assigned.

- Studies blueprints, sketches, drawings, manuals, specifications or sample parts to determine dimensions and tolerances of finished workpiece, sequence of operations, and setup requirements.

- Measures, marks, and scribes dimensions and reference points on material or workpiece as guides for subsequent machining.

- Selects, aligns, and secures holding fixtures, cutting tools, attachments, accessories, and materials on machines such as mills, lathes, jig borers, grinders, and shapers.

- Calculates and sets controls to regulate machining factors such as speed, feed, coolant flow, and depth and angle of cut, or enters commands to retrieve, input, or edit computerized machine control media.

- Starts and observes machine operation to detect malfunctions or out-of-tolerance machining, and adjusts machine controls or control media as required.

- Verifies conformance of finished workpiece to specifications.

- Sets up and operates machine on trial run to verify accuracy of machine settings or programmed control data.

- Fits and assembles parts into complete assembly.

- Verifies dimensions and alignment of assembly.

- Installs machined replacement parts in mechanisms, machines, and equipment, and tests operation of unit to ensure functionality and performance.

- Develops specifications from general description and draws sketch of part or product to be fabricated.

Automation Technician

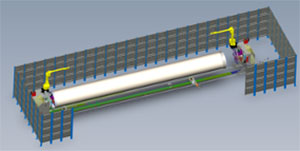

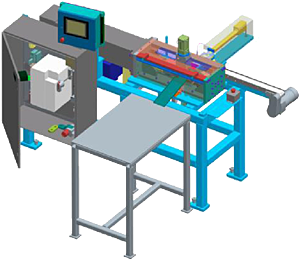

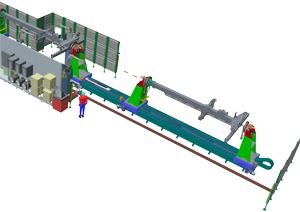

Engineers robotic work cells for integration in the shop by performing the following duties.

Essential Duties and Responsibilities include the following. Other duties may be assigned.

- Creates robotic concepts to support quoting.

- Develops welding procedures and parameters for robotic applications as required by customer specifications.

- Performs reach studies in offline programming software.

- Assists with development of end of arm tooling, grippers, and machine vision programming

- Performs robotic time studies including machine time, cycle time, load time, and overall tact time.

- Recommends weld processes and consumables as required to meet customer specifications.

- Assists with robot cell integration process including programming and run off at customer site.

- Provides support to fabrication shop for welding support, as needed.

Toolmaker

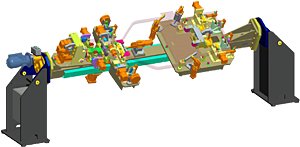

Analyzes specifications, lays out metal stock, sets up and operates machine tools, and fits and assembles parts to fabricate and repair metalworking dies, cutting tools, jigs and fixtures, gauges, and machinist handtools by performing the following duties.

Essential Duties and Responsibilities include the following. Other duties may be assigned.

- Studies specifications such as blueprints, sketches, models, or descriptions, and visualizes product to determine materials required and machines to be used to fabricate parts.

- Computes dimensions, plans layout, and determines assembly method and sequence of operations.

- Measures, marks, and scribes metal stock for machining.

- Sets up and operates machine tools such as lathes, milling machine, shaper, and grinder, to machine parts, and verifies conformance of machined parts to specifications.

- Lifts machined parts and positions and secures parts on surface plate or worktable.

- Smooths flat and contoured surfaces, and fits and assembles parts together and into assemblies and mechanisms.

- Verifies dimensions, alignments, and clearances.

- Heat treats tools or parts.

- Examines standard or previously used dies, tools, and jigs and fixtures, and recommends design modifications regarding construction and function of part.

- Complies with all safety rules and regulations.

Project Manager-Sales

Accepting Resumes for a full time Project Manager. Candidates must have prior technical sales knowledge. Candidate should possess and AAS or equivalent and be familiar with automation, machining, welding, and general manufacturing practices.

- Minimum Experience

- 2 yrs sales experience

- Must be willing to work up to 50 hours per week

- Must be willing to travel. US based up to 25%

- Must have mechanical aptitude or prior experience in manufacturing environment

- Positive attitude, team player

- Interface with customers on a regular basis

This is a salaried position and offers a very attractive wage and benefits package!

Design Engineer 2 Job Description

Designs complex welding and machining holding fixtures, robotic welding cells, special machines and related jigs, dies, and fixtures by performing the following duties.

Essential Duties and Responsibilities include the following. Other duties may be assigned.

- Studies specifications, engineering blueprints, tool orders, and shop data.

- Confers with engineering and shop personnel to resolve design problems related to material characteristics, dimensional tolerances, service requirements, manufacturing procedures, and cost.

- Applies algebraic and geometric formulas and standard tool engineering data to develop tool configuration.

- Selects standard items such as bushings, clamps, shims, hydraulic components, electrical controls, and locating devices to incorporate into tool design.

- Has a basic understanding of hydraulic, pneumatic and electrical controls.

- Draws preliminary sketches and prepares layout and detail drawings.

- Complies with all HTL and customer design and drawings standards.

- Complies with all safety rules and regulations.

Supervisory Responsibilities

- This Job has no supervisory responsibilities.

Qualifications

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

Education and/or Experience:

Associate’s degree, plus at least 3 years of experience and/or training in advanced tooling and fixture design utilizing parametric design software; or equivalent combination of education and experience.

Language Skills:

Ability to read, analyze, and interpret general business periodicals, professional journals, technical procedures, or governmental regulations. Ability to write reports, business correspondence, and procedure manuals. Ability to effectively present information and respond to questions from groups of managers, employees and customers.

Mathematical Skills:

Ability to work with mathematical concepts such as probability and statistical inference, and fundamentals of plane and solid geometry and trigonometry. Ability to apply concepts such as fractions, percentages, ratios, and proportions to practical situations.

Reasoning Ability:

Ability to solve practical problems and deal with a variety of concrete variables in situations where only limited standardization exists. Ability to interpret a variety of instructions furnished in written, oral, diagram, or schedule form.

Computer Skills:

- Knowledge of Pro/Engineer software required, WF4.0 preferred.

- Knowledge of MS Office preferred.

- Pneumatic, hydraulic and electrical design experience preferred.

- Robotic integration experience preferred.

Other Qualifications:

- Experience and knowledge in general design and development of sheet metal, castings, tooling and utilizing hydraulics, pneumatics and electrical systems required.

- Must be willing and able to work overtime, up to 60 hours per week, including Saturdays and Sundays.

- Must be able to work flexible hours.

- Must be detail-oriented and self-motivated with the ability to work with limited direction.

- Must be dependable and reliable with a positive work history in attendance.

- Must possess excellent mechanical aptitude.

Physical Demands:

The physical demands described are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

Other Qualifications:

The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

The noise level in the work environment is usually moderate. The employee is occasionally exposed to outdoor weather conditions. Parts of the work environment are not climate-controlled.