Recent Projects

Robotic Material Handling System

- Over 550lb load handling capacity

- Accurately Palletizes parts from machining center to 5 unique bins based on part size.

- Increased efficiency over 35% for the process it replaced

- Intelligent feedback provides 99% uptime, and 95% quality increase

- Runs 3 shifts 22hrs per day 6 days per week

- Includes vision inspection, and laser ablation cleaning system

- Includes RFID labeling technology

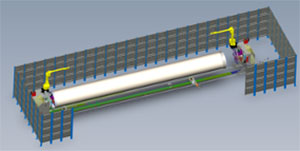

Robotic Welding System – Large Vessel Weldments

- Automatic Seam Finding and Tracking

- 50’ pipe sections, 24” to 96” diameters

- All tooling and automation custom engineered for this solution to optimize efficiency

- 44% efficiency improvement

- 35% quality improvement

- Virtually eliminated all rework on code welds

- Greatly increased operator safety risk

- 99% employee injury reduction

- Increased sales volume by 15% in the first month

- 4 month ROI

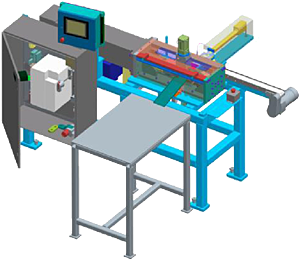

Smart Tooling – Tack Welding Fixture

- Manual, Semi-Automatic, and Automatic clamping modes

- Clamps with force and positioner sensors to ensure an in tolerance part everytime

- Tool comes with 15” color touch screen display

- Display allows for operator input and shift notes, etc for engineering

- Display allows for Work instructions for every step of the build process

- Each load sequence displays a picture for the operator to reference

- Tool verifies part presence/absence/and correct fit for each process step

- Tool tracks number of welds placed, and number of inches of weld for each step

- 55% efficiency increase

- 95% rework reduction

- 8 month ROI

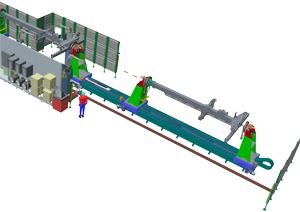

Complete manufacturing transfer line – ROPS cab manufacturing

- Manufacturing of all sub components

- Sub Component Tack fixtures auto loaded into sub welding robots

- Sub Component Welding robots auto unloaded into final welding robots

- Final welding robots auto unloaded into paint line

- 9 month ROI

- Complete cab weldment every 24-30 minutes depending on options

- 6 of these lines installed in North America in the last 4 years

Material Handling Robot with Plasma Arc Welding

- Produces 1 part every 12 seconds

- Intuitive Recipe based programming capabilities

- 12" full color HMI touch screen

- Automated infeed and outfeed with vision sensing

- RIA Compliant

Robotic Material Handling Bushing Press

- Press forces up to 50,000 lbs

- Automatically presses 14 bushings per cycle

- Automatic magazine bushing feeder

- Automatic bushing arbor tool change

- Servo controlled bushing press (no hydraulics)

- Full color HMI w/intuitive recipe based programming

Automated Pull Tester

- Provides up to 144,000lbs of pull force

- Accurately measures stress/strain within +/-.001"

- Automatic part reject capabilities

- Automatic data reporting to plant network

Tack Welding Fixture with Hydraulic Clamping

- Locates 126 individual pieces

- 44 hydraulic cylinders with 12 sequences

- Hawk Technology Ltd Patented tooling ball system

Tack Welding Fixture with Pneumatic Clamping

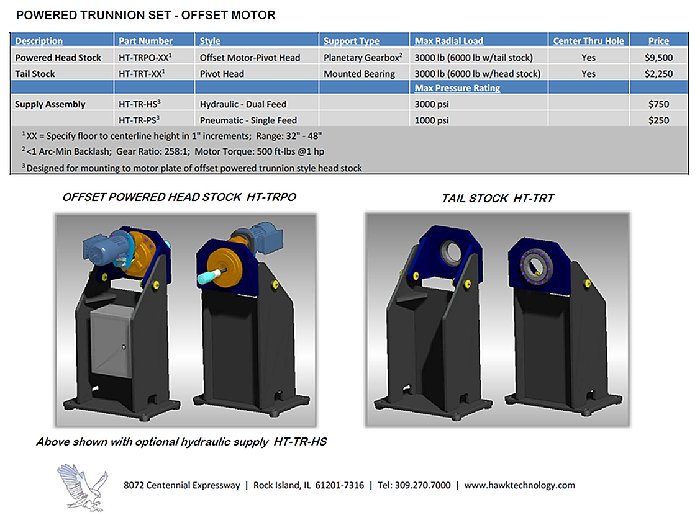

- Powered trunnions with up to 600 ft/lbs of torque

- Integral backbone to provide outstanding weld access

- Hardened locators with shimmability

- Six degrees of freedom accurately for every detail

- Full 3d parametric concurrent design

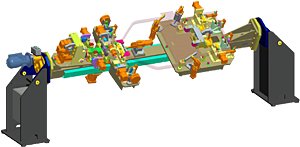

Three arm welding system

- 20 axis welding system

- 12,000lb capacity

- 85' of linear track

- Three welding arcs simultaneously

Vision Inspection System

- 8 lane simultaneous inspection

- Speeds up to 300 parts per minute each lane

- Achieved .05% repeatability for inspection

- Food Grade rated

- Over 40 installed systems operating worldwide

Vision Inspection System

- 8 lane simultaneous inspection

- Speeds up to 300 parts per minute each lane

- Achieved .05% repeatability for inspection

- Food Grade rated

- Over 40 installed systems operating worldwide

VERY LIMITED SPECIAL OFFER!!

Hawk Technology Ltd has stock on several sets of 42" Centerline height powered and manual trunnions. We are offering to deliver and set up trunnions on site at your location FREE OF CHARGE!!! We will give you the trunnions to use for a period of 45 days in exchange for your candid feedback of our product. If you like them, make payment arrangements, if you don't we will retrieve them at no cost to you! Call today limited availability! These will go quickly, don't miss out on this amazing opportunity! Call Josh Clare at 563-580-1064.

Hawk Technology, Ltd. | 8072 Centennial Expressway, Rock Island, IL 61201-7316

Phone 309.270.7000 | E-mail sales@hawktechnology.com