Robotic Material Handling System

- Over 550lb load handling capacity

- Accurately Palletizes parts from machining center to 5 unique bins based on part size.

- Increased efficiency over 35% for the process it replaced

- Intelligent feedback provides 99% uptime, and 95% quality increase

- Runs 3 shifts 22hrs per day 6 days per week

- Includes vision inspection, and laser ablation cleaning system

- Includes RFID labeling technology

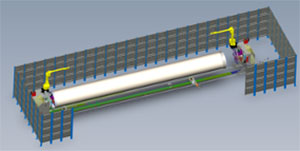

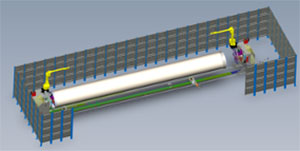

Robotic Welding System – Large Vessel Weldments

- Automatic Seam Finding and Tracking

- 50’ pipe sections, 24” to 96” diameters

- All tooling and automation custom engineered for this solution to optimize efficiency

- 44% efficiency improvement

- 35% quality improvement

- Virtually eliminated all rework on code welds

- Greatly increased operator safety risk

- 99% employee injury reduction

- Increased sales volume by 15% in the first month

- 4 month ROI

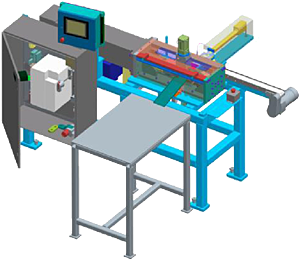

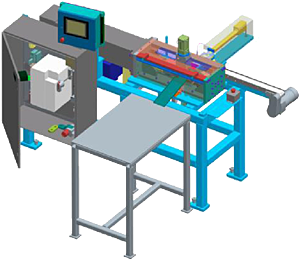

Smart Tooling – Tack Welding Fixture

- Manual, Semi-Automatic, and Automatic clamping modes

- Clamps with force and positioner sensors to ensure an in tolerance part everytime

- Tool comes with 15” color touch screen display

- Display allows for operator input and shift notes, etc for engineering

- Display allows for Work instructions for every step of the build process

- Each load sequence displays a picture for the operator to reference

- Tool verifies part presence/absence/and correct fit for each process step

- Tool tracks number of welds placed, and number of inches of weld for each step

- 55% efficiency increase

- 95% rework reduction

- 8 month ROI

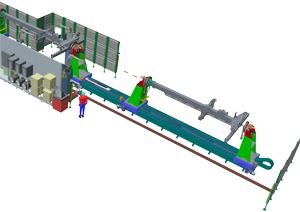

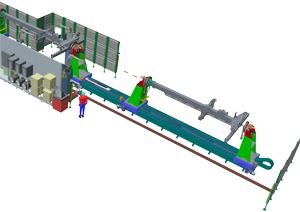

Complete manufacturing transfer line – ROPS cab manufacturing

- Manufacturing of all sub components

- Sub Component Tack fixtures auto loaded into sub welding robots

- Sub Component Welding robots auto unloaded into final welding robots

- Final welding robots auto unloaded into paint line

- 9 month ROI

- Complete cab weldment every 24-30 minutes depending on options

- 6 of these lines installed in North America in the last 4 years

Material Handling Robot with Plasma Arc Welding

- Produces 1 part every 12 seconds

- Intuitive Recipe based programming capabilities

- 12" full color HMI touch screen

- Automated infeed and outfeed with vision sensing

- RIA Compliant

Robotic Material Handling Bushing Press

- Press forces up to 50,000 lbs

- Automatically presses 14 bushings per cycle

- Automatic magazine bushing feeder

- Automatic bushing arbor tool change

- Servo controlled bushing press (no hydraulics)

- Full color HMI w/intuitive recipe based programming

Automated Pull Tester

- Provides up to 144,000lbs of pull force

- Accurately measures stress/strain within +/-.001"

- Automatic part reject capabilities

- Automatic data reporting to plant network

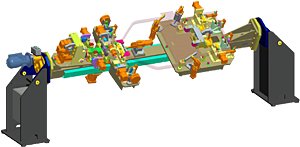

Tack Welding Fixture with Hydraulic Clamping

- Locates 126 individual pieces

- 44 hydraulic cylinders with 12 sequences

- Hawk Technology Ltd Patented tooling ball system

Tack Welding Fixture with Pneumatic Clamping

- Powered trunnions with up to 600 ft/lbs of torque

- Integral backbone to provide outstanding weld access

- Hardened locators with shimmability

- Six degrees of freedom accurately for every detail

- Full 3d parametric concurrent design

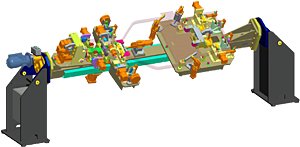

Three arm welding system

- 20 axis welding system

- 12,000lb capacity

- 85' of linear track

- Three welding arcs simultaneously

Vision Inspection System

- 8 lane simultaneous inspection

- Speeds up to 300 parts per minute each lane

- Achieved .05% repeatability for inspection

- Food Grade rated

- Over 40 installed systems operating worldwide

Vision Inspection System

- 8 lane simultaneous inspection

- Speeds up to 300 parts per minute each lane

- Achieved .05% repeatability for inspection

- Food Grade rated

- Over 40 installed systems operating worldwide